Ideal applications

Large Volume, Low concentration airflow.

2021 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

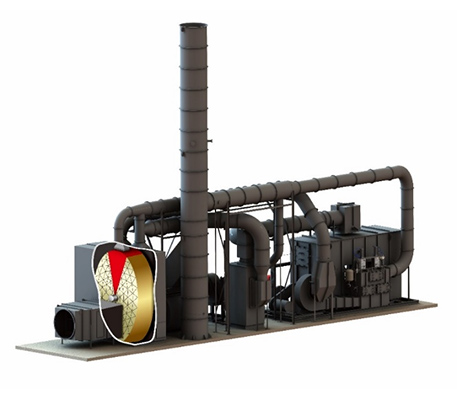

The Anguil Emission Concentrator is an adsorption system that greatly concentrate large volume, low concentration process exhaust into a much smaller, higher concentrated air stream. The concentrated flow is then sent to a thermal or catalytic oxidizer with much smaller in size, significantly reducing capital cost and the operating fuel consumption.

The rotor concentrator system is an integrated air pollution control device which uses proprietary adsorbents in a honeycomb structure to remove volatile organic compounds (VOCs) from exhaust emission. When the large volum and low concentrated flow is drawn into the rotor concentrator, the VOCs is adsorbed onto the zeolite. The majority (approximately 90-95% of the total air volume) of this clean air is then exhausted to atmosphere. A small portion of the air stream (approximately 5-10% of the total air volume) is heated to an elevated temperature to be used as desorption air.

The concentrator rotor spins continuously at a very slow rate, transporting adsorbed pollutants into a desorption section. In the desorption section, the VOCs are desorbed or released from the adsorptive media with the low volume heated airstream. This low volume, high VOC-laden air is then processed by an oxidizer.

Large Volume, Low concentration airflow.

1. Multiple rotors in series or parallel for even higher DRE or higher airflows.

2. Various zeolite substrate options to prevent polymerization.

3. High-efficiency filter to protect the adsorbent from process particulate exhaust.

4. Various options for desorption air heat.

5. Multiple oxidizers configuration coupled for VOCs destruction.

6. Fully-integrated concentrator – oxidizer systems, including common controls stream.